Agriculture

February 29, 2024

Updated on March 14, 2024

·Created on October 27, 2022

Hemp-lime composites for building insulation.

Hempcrete is a composite made with hemp hurd and lime binder. It comes in two forms: cast in place and in premade blocks. It is a biocomposite building system that is used primarily for thermal envelope applications.

Target SDGs

SDG 11: Sustainable Cities and Communities

SDG 12: Responsible Consumption and Production

Market Suggested Retail Price

$9.20

Target Users (Target Impact Group)

Small and Medium-sized Enterprises

Distributors / Implementing Organizations

The product is sold online by the manufacturer

Competitive Landscape

Direct competitors include Wricks - Reinventing Brick Industry, Watershed Block, and RePlast.

Countries

United States

Manufacturing/Building Method

The product can be installed by casting in place using molds or as pre-cured blocks. The company is building a manufacturing facility in Jerome, Idaho (USA) that will be completed in 2022

Intellectural Property Type

Trademark

User Provision Model

Users can obtain the product by purchasing online

Distributions to Date Status

Unknown

Unit dimensions (cm)

60 x 30 and 15 cm depth

Primary materials

limestone, industrial hemp stalks

Complimentary materials

Unknown

Fire Resistance (hr)

Unknown

Thermal Insulation Capacity

Unknown

Compressive Strength (MPa)

300 kPA (hempcrete blocks)

Suitable Climates

Not suitable for humid environments

Design Specifications

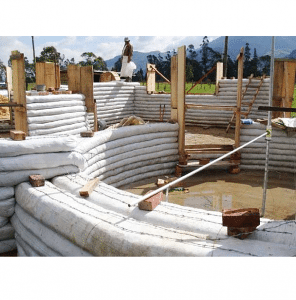

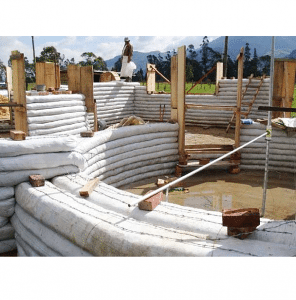

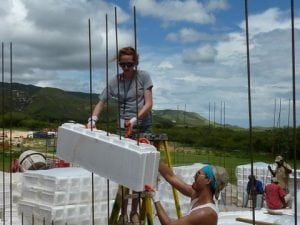

Hempcrete can be built in two forms: cast in place or purchased in blocks. Cast in place is an installation technique that involves using form boards and packing the Hempcrete in between form boards to create walls. Hempcrete blocks are a pre-cured solution for building insulation.

Hempcrete is a monolithic wall system that is best used as a thermal envelope for energy efficient building projects. It can be used for both renovations and new buildings.

Technical Support

Provided by the manufacturer

Replacement Components

Provided by the manufacturer

Lifecycle

Unknown

Manufacturer Specified Performance Parameters

Plant-based resource: Hempcrete is made with a renewable plant-based commodity, the hemps’ “Hurd” that is typically considered a waste product.

Carbon sequestration: Hemp absorbs CO2 during its growth. After mixing the hurd with the binder, CO2 is absorbed during the solidification process. 1 ft3 of hempcrete building material offsets approx- imately 7.27 lbeq of CO2.

Insulation: Cast in place 10” thick hempcrete presents R2.5/inch.

Moisture: It is capable of being exposed to humidity while maintaining their R value.

Sounds: Hempcrete attenuates sound transmission.

Vetted Performance Status

Intertek performed a fire test following ASTME 84. The hempcrete specimen obtained a 0 for flame spread and smoke development, on a scale from 0 to 450, making it fireproof

Safety

Potential hazards related to breathing powder dust of Limestrong (the products’ binder).

Complementary Technical Systems

The manufacturer also sells mixer machines to prepare Hempcrete.

Academic Research and References

“Resources”, Hempitecture Inc., accessed on March 14, 2024, https://www.hempitecture.com/resources/

Compliance with regulations

Unknown

Evaluation methods

Hempcrete was tested for flame and smoke.

Other Information

“Products”, Hempitecture Inc., accessed on March 14, 2024, https://www.hempitecture.com/products/

“Shop”, Hempitecture Inc., accessed on March 14, 2024, https://www.hempitecture.com/shop/

Hemp Today, 2020, Hempcrete scores a perfect ‘O’ under ASTM fire testing in USA

Agriculture

February 29, 2024

Agriculture

February 29, 2024

Implemented by

Hydraform

Agriculture

March 7, 2024

Implemented by

Francis Kennedy

Agriculture

March 4, 2024

Implemented by

Lazarian World Homes

Agriculture

March 6, 2024

Agriculture

June 30, 2024

Implemented by

Lifeway Solar

Agriculture

June 23, 2024

Implemented by

Carpolo (Mohammad Nabaa & Ralph Khairallah)

Agriculture

March 13, 2024

Implemented by

Mycotech Lab (MYCL)

Agriculture

March 13, 2024

Implemented by

Angirus Ind Pvt. Ltd.

Agriculture

March 14, 2024

Implemented by

Straw Resource Ltd.

Have thoughts on how we can improve?

Give Us Feedback

There is the the start of some good information here, but it could be more complete.

The company that is featured here is Hempitecture and they are based in Idaho. They have become more focused on non-woven hemp batt insulation, which they call Hemp Wool, and are manufacturing it at their facility in Idaho. This is different than hempcrete, as it is a replacement for fiberglass and mineral wool insulations.

Hempcrete is one for of monolithic biocomposites, and similar to cob and adobe, and hemp hurd is one of many bioaggregates that can be used for this type of material. It is a lightweight, mineral-based wall infill material and actually comes in a number of different formats: site-mixed and cast monolithic building envelopes, floors and ceiling insulations; bricks (see Cannabric in Spain); blocks (see Isohemp in Belgium, Senini-Tecnocanapa in Italy, or Canhamor in Portugal); structural blocks (see Just Biofiber from Alberta); T-blocks or Z-blocks to fit between studs (see Divita Hemp Blocks in Alberta, and Sativa Building Systems in Wisconsin); full structural wall sections (see Wall’up in France and Homeland Hempcrete in North Dakota); spray applied systems (see Ereasy – repped by Americhanvre in the US – and 3CM from France, and Senini from Italy); and panels (see Calmura Natural Walls in British Columbia.)

Happy to add more information if needed.