Agriculture

December 16, 2023

HPS Biomass Gasification Power Plant

Read SolutionImplemented by

Husk Power Systems (HPS)

discontinued

discontinued

Updated on November 13, 2024

·Created on June 9, 2017

The PP20 power pallet is a biomass gasifier system that converts biomass into heat and electricity.

The PP20 Power Pallets product is a biomass gasifier system that converts dense biomass (such as wood chips and nut shells) into heat and electricity. It is a compact, integrated system that delivers electricity under $1.50/Watt. The product was designed and distributed by All Power Labs. The PP20 was discontinued and replaced by the PP30 Power Pallets, which is more efficient in power output, thermal capabilities, new grid-tie hardware, filtration and noise-reduction functionalities for cooling fans, larger ash/dust collector, an added hopper to reduce occurrence of feedstock jams, and new three-phase genheads.

Target SDGs

SDG 7: Affordable and Clean Energy

Market Suggested Retail Price

$40,000.00

Target Users (Target Impact Group)

Community, Small and Medium-sized Enterprises

Distributors / Implementing Organizations

This product has been implemented and distributed by All Power Labs.

Competitive Landscape

Direct competitors include Sistema Biobolsa, Flexi Biogas BG5, SimGas GesiShamba, and NETPRO biomass plant.

Countries

Benin, Chad, China, Colombia, Haiti, Kenya, Liberia, Malawi, Mexico, Philippines, Thailand, United States

Manufacturing/Building Method

This product is individually manufactured to order.

Intellectural Property Type

Patent

User Provision Model

Users can obtain this product directly from manufacturer.

Distributions to Date Status

As of 2017, approximately 100 units have been distributed.Interview with representative in 2017

Power rating (W or kW)

15 kW at 50 Hz, 18 kW at 60 Hz

Available energy type (mechanical, thermal, electrical)

Electrical (18 kW); thermal (20 kW)

Description of biomass source(s)

Dense biomass such as nut shells and wood chips

Biomass input requirements (kg per hour)

0.33 m3 every 3 hours

Other input requirements (amount per hour)

N/A

Combustor type

Internal combustion engine

Biomass conversion efficiency (%)

Upwards of 35%; 1.2 kg of feedstock to 1 kWh of electricity

Particulate matter and CO emissions (ppm)

N/A

System dimensions (m)

N/A

Design Specifications

The PP20 Power Pallet is made up of a GEK Hot TOTTI multi-stage gasifier, spark fired industrial engine, generator head, and electronic controller. The system automatically adjusts syngas/air mixture via a wide band Bosch oxygen sensor, shakes the grate when needed, and removes ash via a mechanical auger. The Process Control Unit (PCU) monitors and responds to all internal reactor, filter and engine conditions, and displays the results on an LCD screen.

Power Pallet genheads are configurable to single, split or three phase, at 120/208/240 Vac, 60 Hz or 50 Hz, and are also available with an Optional Grid-Tie package allowing the PP20 to work with other power generating devices–such as wind or solar, as well as with additional Power Pallets, utilities or micro-grids–to generate reliable synchronized power.

The product has a continuous power rating of 15 kW at 50 Hz, and 18 kW at 60 Hz. The sound level at 30 feet is 85 dB. The biomass consumption is 1.2 kg/kWh - 2.5 lbs/kWh. The run time per hopper fill (at 250 kg/m3 fuel density) is 10 hrs at 5 kW, 5 hrs at 10 kW, and 3 hrs at 15 kW. The maximum continuous operation time is over 12 hours, and the start-up time is 10-20 minutes.

Operating conditions include an ambient temperature of 5-40 °C (40-100 °F), and humidity level of 5-95% RH. The installed footprint without the ash vessel or grid tie is 1.36 x 1.36 m (53.5 x 53.5 inches). In addition, the manufacturer suggests that the product be placed in a well-ventilated protected from rain and direct sun.

Technical Support

Provided by the manufacturer.

Replacement Components

Replaceable components include gaskets, vessels, and tubing. Additional components can be made available upon request to All Power Labs.

Lifecycle

This product includes warranty at the manufacturer's discretion, with an expected lifetime of over six years with routine maintenance.

Manufacturer Specified Performance Parameters

Designer specified performance targets include: minimized component architecture, compact, improved tar conversion, fuel flexibility, and improved general efficiency.

Vetted Performance Status

Testing performed by researchers at Duke University attempted to model the dynamic performance of the PP20 Power Pallet by characterizing the fuel ratio, run time, etc. of the equipment, and creating a transfer function that captured the system performance. Overall, it was found that the system has approximately a 0.34 second time delay, a 0.10 second time constant, and a 600 second delay at PP20 startup. Other characteristics of the PP20 could not be defined given their significant dependence on environmental factors.

Safety

Potential hazards related to the operation of this product include exposure to flammable gases. Additional safety handles and warnings are included on the product.

Complementary Technical Systems

Complementary technical systems include the combined heat and power (CHP) module.

Academic Research and References

Ayanian C. and Desai S., 2016, “Control of Biodiesel Generator Set in Biomass Gasification Emulation for Use in Emergency Energy Module (EEM),” Duke University.

Mason, J. M. 2010. System and Method for Downdraft Gasification.

Power Pallet – PP20. n.d. All Power Labs.

Warranty and Sales Guarantee. n.d. All Power Labs.

PP20 – Discontinued. n.d. All Power Labs.

Combined Hear and Power (CHP) Accessory. n.d. All Power Labs.

PP20 Series Power Pack. n.d. Acuity Controls.

Compliance with regulations

The PP20 is ROHS compliant with the Plenum UL2043 Standard and is also Title 24 Compliant.

Evaluation methods

The manufacturer cites load testing for run time, sustained power output, and low threshold tests as evaluation methods. This product has not been specifically evaluated in the field with end-users (Interview with Representative).

Agriculture

December 16, 2023

Implemented by

Husk Power Systems (HPS)

Agriculture

December 17, 2024

Implemented by

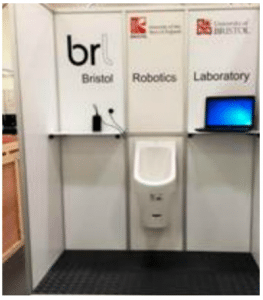

Bristol Robotics Laboratory

Agriculture

January 28, 2024

Implemented by

Fenix International

Agriculture

January 3, 2024

Implemented by

ovSolar

Agriculture

December 16, 2024

Implemented by

Renewit

Agriculture

December 10, 2024

Implemented by

Renewit

Agriculture

January 5, 2024

Implemented by

MeraGao Power

Agriculture

February 13, 2024

Implemented by

Village Infrastructure Angels (VIA)

Agriculture

December 23, 2024

Implemented by

Guangzhou Anern Energy Technology Co., Ltd

Agriculture

November 22, 2024

Implemented by

Appropriate Energy Saving Technologies Limited (AEST)

Have thoughts on how we can improve?

Give Us Feedback

Details of success and performance in field settings would be helpful, and should be available if 100 units have been deployed?