Agriculture

January 8, 2024

GravityPure UF

Read SolutionImplemented by

Healing Waters International

Updated on January 3, 2024

·Created on September 10, 2016

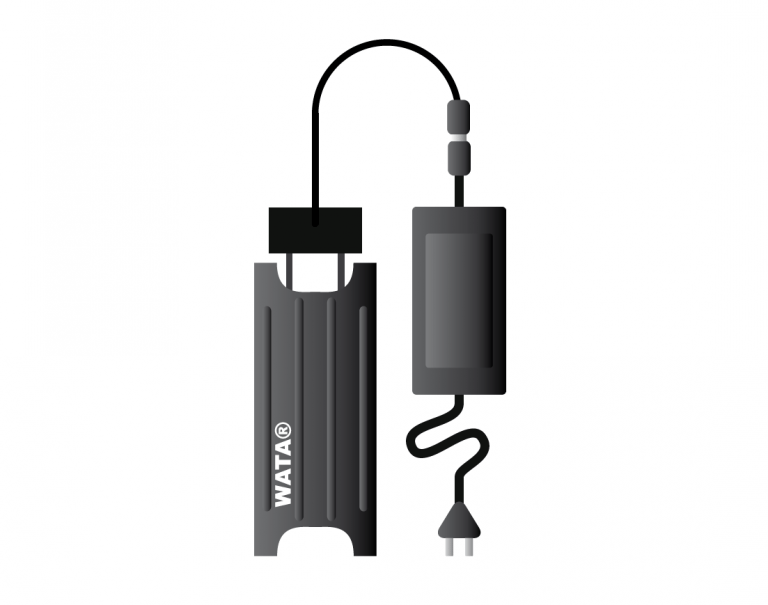

WATA technology enables the local production of sodium hypochlorite (chlorine) for water disinfection and treatment purposes.

WATA technology is a portable device that allows users to make their own chlorine using just water, salt, and electricity. The system converts a measure of salt and water into sodium hypochlorite (bleach) by a process called electrolysis. It is designed by the Antenna Foundation based in Geneva, Switzerland. This product is commercially available and comes in 5 different sizes depending upon the quantity of active chlorine made from 0.5 to 60 liters.

Target SDGs

SDG 6: Clean Water and Sanitation

SDG 3: Good Health and Well-Being

Market Suggested Retail Price

$417.00

Target Users (Target Impact Group)

Community, Small and Medium-sized Enterprises, Public Sector Agencies, NGOs

Distributors / Implementing Organizations

This product has been implemented by the Ministry of Health of Burkina Faso and Hydrolic in Cambodia.

Competitive Landscape

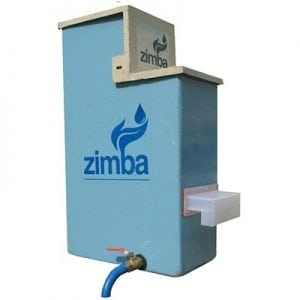

Direct competitors include PurAll Water Purification, MSR SE200 Community Chlorine Maker, P&G Purifier of Water, Lotus Water Chlorine Dosing Device, Zimba automatic chlorine dispenser, Aquatab Tablets, and WaterGuard.

Countries

Burkina Faso, Cambodia, Comoros, Congo (Kinshasa), Guinea, India, Mali, Nepal, Pakistan, Rwanda, Zambia

Manufacturing/Building Method

The dispenser is installed near a water source. It is fitted with a valve that consistently delivers a precise 3 ml dose of chlorine. The tank is filled with sodium hypochlorite (chlorine) solution and installed at the water source in a protective casing. Community members go to their water source, place their bucket or jerrycan under the dispenser, turn the valve to dispense the correct amount of chlorine, and then fill the bucket with water. The chlorine disinfects the water within 30 minutes, then the chlorine residual prevents recontamination for 2-3 days.

Intellectural Property Type

Trademark

User Provision Model

Users can contact country-specific partners for the distribution or can purchase directly from the website.

Distributions to Date Status

As of 2019, more than 5,000 products have been distributed.

Active Chemical and concentration (%)

0.6% sodium hypochlorite

Form

Liquid

Dosing method: Batch or flow-through

Batch

Dosing method: Automatic or manual

Manual

Dosing quantity

0.25 mL of 6 g/L sodium hypochlorite solution

Contact time (min)

30

Target free disinfectant residual (mg/L)

0.5-1

Bacteria reduction

Unknown

Virus reduction

Unknown

Protozoa reduction

Unknown

Heavy metals and/or arsenic reduction

Unknown

Treatment lifespan (days)

Usually 24 hours but can be stabilized for up to 6 months with addition of caustic soda.

Maximum recommended influent turbidity level (NTU)

Water to be treated should be of low turbidity (<5 NTU)

Design Specifications

WATA is an electronic device used to produce active chlorine for disinfection out of salt, water, and electricity. The WATA products produce the sodium hypochlorite equivalent to 6 g/L (0.6%) at different rates (1 g/hr to 80 g/hr) depending on the model. One liter of the solution is enough to treat 4,000 L of drinking water. Supplies required: clear water, salt (400 g/L of water), and electricity (30 W or 110-220 V). WATTA includes 5 devices with different active chlorine production capacities. The design specification for individual WATTA products can be found here.

Technical Support

Provided by the manufacturer (Antenna Technologies).

Replacement Components

Consumables can be purchased online from Antenna Technologies.

Lifecycle

This product has a 2-year warranty and a lifecycle of approximately 5 years assuming 5 productions a week.

Manufacturer Specified Performance Parameters

Designer specified performance targets include: lightweight, durable, portable, locally produced, and low-cost. Moreover, this filter was also designed to prepare active chlorine solution that can be used to treat drinking water or disinfect any objects or surfaces.

Vetted Performance Status

Antenna views the continued support from customers as evidence of vetted performance. Correspondence with manufacturer WATA devices have been sold for almost 10 years to large organizations such as WHO, ICRC, UNICEF, Swiss Agency for Development and Cooperation, MSF, OXFAM, HELVETAS, CARITAS, and others.

Safety

Limestone deposits are formed during production which needs to be cleaned with 1:1 clean water and vinegar solution to ensure efficiency.

Ideally, the power supply is to be placed in a room adjacent to the production room. If this is not possible, place it as far as possible from the container where the chlorine is produced, in order to avoid contact with chlorine vapor which is highly corrosive.

The power supply should not be placed on the floor level and the devices need to always be immersed in the saltwater solution before being plugged into the power supply. The devices need to be rinsed with clear water after each production.

Complementary Technical Systems

WataTest, WataBlue reagents.

Academic Research and References

D von der Weid, 2015, Infection prevention and patient safety improvement in developing countries thanks to sodium hypochlorite production devices; Antimicrobial Resistance and Infection Control.

Reyna Robles and Carole De Bazignan, 2014, The Watasol Approach for a Sustainable Access To Safe Water; GRF Davos Planet@Risk: Special Issue on One Health (Part II/II).Vol 2, No 4.

“Household Water Treatment and Safe Storage in Refugee Situations v25, not field tested,” Ben-harvey.org. Available: http://www.ben-harvey.org/UNHCR/WASH-Manual/Wiki/images/2/2c/Household_Water_Treatment_and_Safe_Storage_in_Refugee_Settings_-_DRAFT_(UNHCR).pdf

Goal 6. (n.d.). Sdgs.un.org. Available: https://sdgs.un.org/goals/goal6

“ORDER – WataTM,” WataTM, 16-Nov-2022. Available: https://watatechnology.com/en/order/

“TRAITEMENT DE L’EAU – WataTM,” WataTM, 12-May-2021. Available: https://watatechnology.com/traitement-de-l-eau/

“Contact,” Antenna.ch. Available: https://antenna.ch/en/contact

D. von der Weid, “Infection prevention and patient safety improvement in developing countries thanks to sodium hypochlorite production devices,” Antimicrob. Resist. Infect. Control, vol. 4, no. S1, 2015. https://aricjournal.biomedcentral.com/counter/pdf/10.1186/2047-2994-4-S1-I8.pdf

Compliance with regulations

WATA technology complies with recommendations of CDC and WHO (2004) for the disinfection in health centers.

Evaluation methods

The product has been field-tested for more than 10 years.

Other Information

Agriculture

January 8, 2024

Implemented by

Healing Waters International

Agriculture

January 3, 2024

Implemented by

Department of Civil and Environmental Engineering, University of Virginia

Agriculture

January 5, 2024

Implemented by

TATA Swach

Agriculture

June 22, 2024

Implemented by

Wello

Agriculture

January 3, 2024

Implemented by

Suprio Das

Agriculture

January 2, 2024

Implemented by

Archimedes Project

Agriculture

January 3, 2024

Implemented by

Helioz

Agriculture

January 18, 2024

Implemented by

Agua Clara LLC

Agriculture

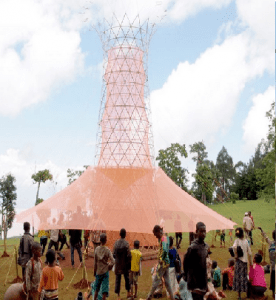

January 26, 2024

Implemented by

Warka Water

Agriculture

January 27, 2024

Implemented by

Medentech Ltd

Have thoughts on how we can improve?

Give Us Feedback